TechScope EZT-II

TechScope EZT-II™ Portable Single-Function EMI Drill Pipe Inspection System for Drill Pipe up to 6-5/8" O.D.

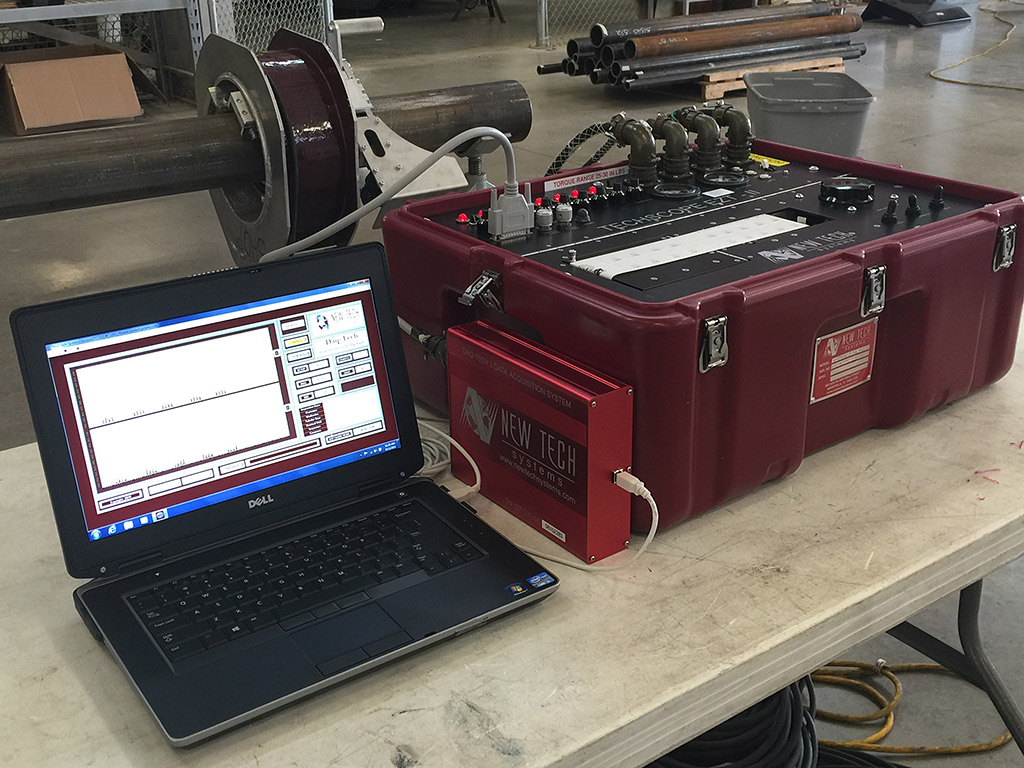

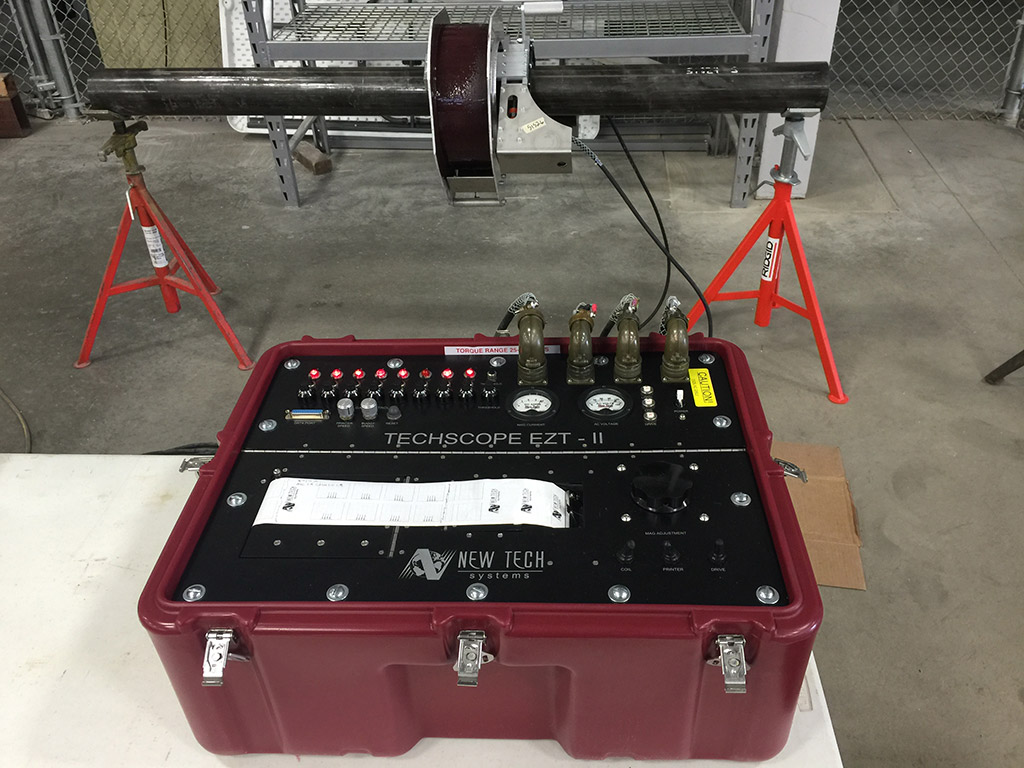

The TechScope EZT-II™ is a portable, rugged, single-function EMI system for inspecting drill pipe and tubing in extreme environments. Transverse flaw detection function is standard on the TechScope EZT-II™. The electronics console consists of a heavy-duty, high-impact synthetic enclosure with a sealed and removable cover. All cable connections are mounted on the top instrumentation panel. The cables have 90-degree connectors to eliminate bending. The TechScope EZT-II™ is designed to meet most industry specifications set forth by API, DS-1, etc.

Product Specifications

| Technical and Performance Data | |

| Capacity: | 2 3/8" to 6 5/8" O.D. drill pipe and tubing |

| Functions: | Transverse flaw detection (MFL) |

| Data Acquisition: | Thermal printer or optional DAQTech III™ computer data acquisition system |

| Production Rate: | Up to 150 ft /minute |

| Inspection Criteria: | The TechScope EZT-II™ is designed to meet most industry specifications (i.e. API, DS-1, etc.) |

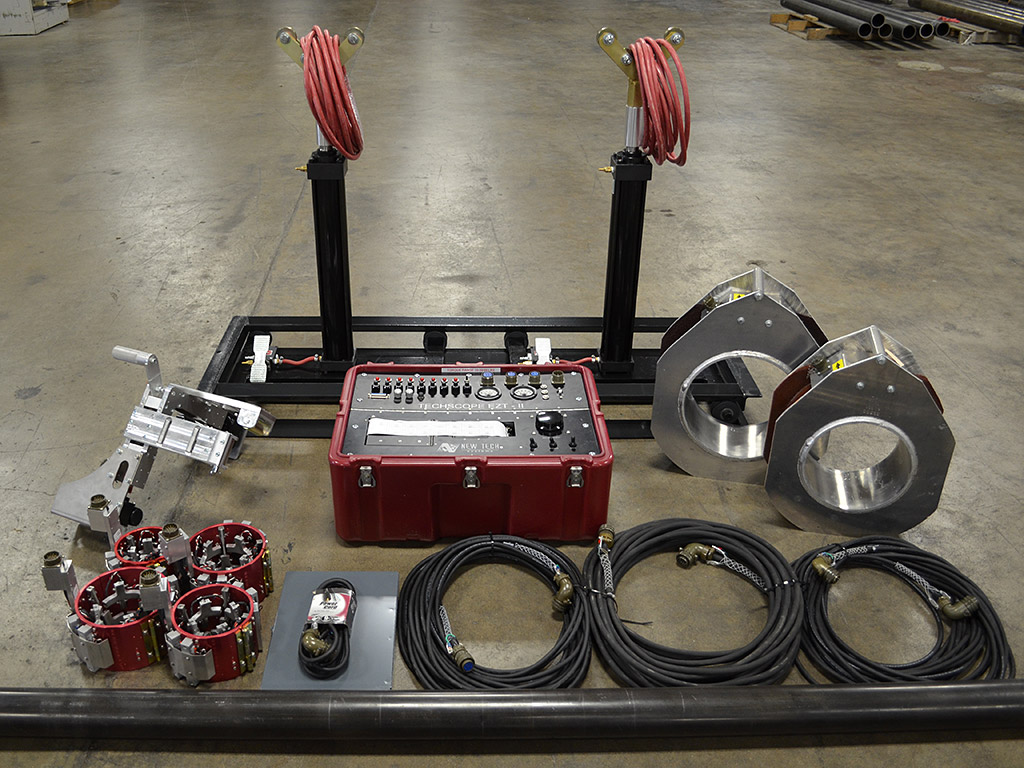

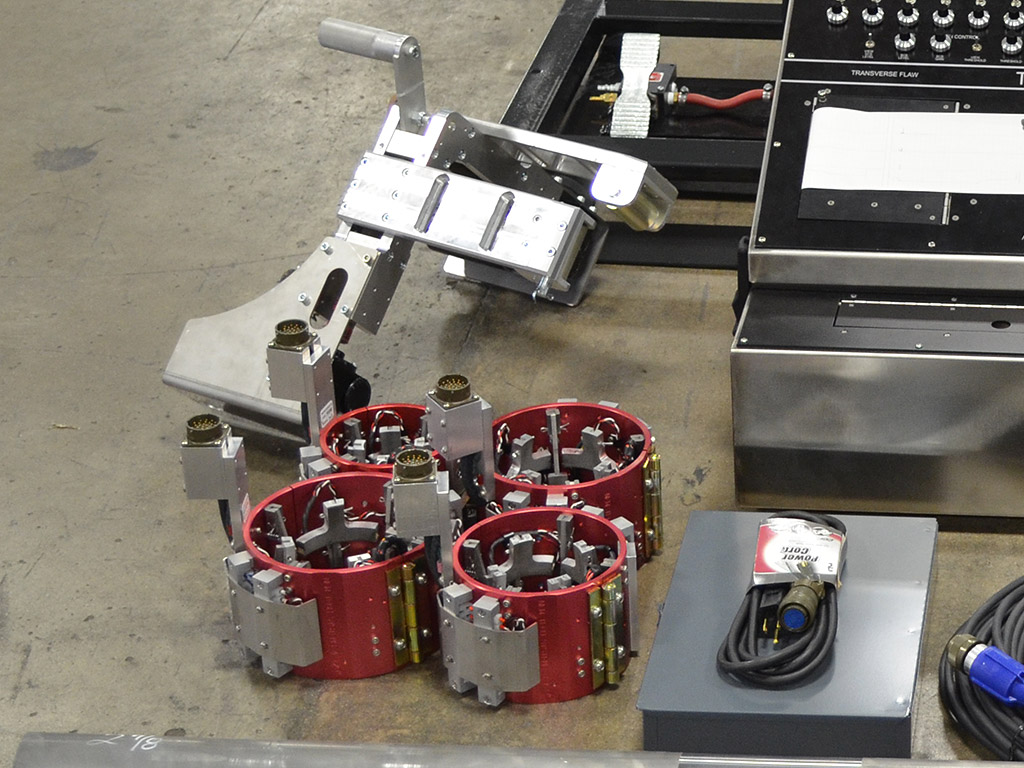

| Major Components: | Electronics console Power, signal, and buggy drive cables High speed buggy drive with variable speed DC motors Powerful DC magnetizing coils Air jack set (standard or Hi-Low models available) Buggy heads (sizes optional) Calibration standards (sizes optional) DAQTech III™ computer data acquisition system (optional) |

Product Images

Mode of Operation

The system is calibrated on a standard at the beginning of the job. The magnetizing coil is placed over the end of the pipe. The buggy drive and head are placed on top of the pipe and the mag coil is placed on the buggy drive. The air jacks lift the pipe so the coil & buggy will clear the pipe racks. The electronics operator then powers the buggy down the pipe and starts the thermal printer (or optional DAQTech III™ computer data acquisition system) and observes the data. When the buggy reaches the other end of the pipe, the jacks lower the pipe to the racks, the buggy and coil are removed and placed on the next pipe. The process is then repeated in the opposite direction.